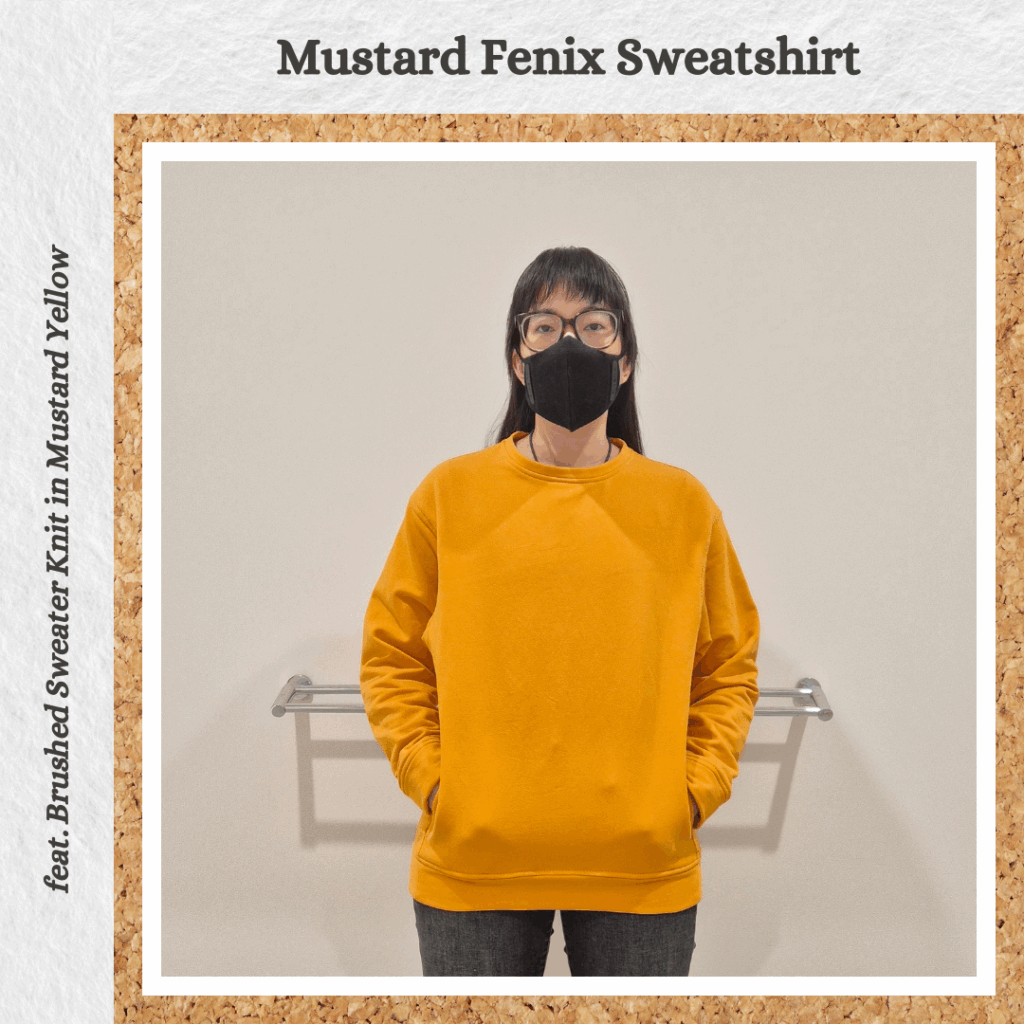

Planning and Design

I like my Manatee Fenix Sweat Shirt a lot, but the rib cuffs do feel a bit loose. Unlike some of their other knit patterns, I don’t think Style Arc include a tip about reducing the length if using rib instead of main fabric. In fact, I think the design intent is to use rib rather than main fabric. So I’ve been wanting to make a version that using main fabric instead, since I’ve established that’s my preference with sweaters.

I think I bought this fabric because it was a medium weight fleece, compared to the heavy weight descriptor of the Good Earth Cotton fleece I used in the Ochre Simpson Sweat Shirt. 245g/m2 versus 320g/m2. I don’t really feel like the GEC fleece is that weighty, so will be interesting to compare. The Wattle Hill Fabric brushed fleece is also 245g/m2 and I feel that is quite light. I guess I didn’t really pay attention to fleece weight until now haha.

Materials

- Pattern

- Fenix Sweat Shirt (Style Arc)

- Fabric

- Brushed Sweater Knit – Mustard Yellow (MaaiDesign)

- Notions

- Maraflex col. 300

- 12mm Cotton Herringbone Tape – Bold Yellow (Remnant Warehouse)

- Maxi-lock 3000yd Polyester Serger Overlocker Thread – Mother Goose

Sustainability Check

👍 The fabric is 97% Cotton and 3% Elastane so technically biodegradable

👍 Maraflex is biodegradable

👍 The herringbone tape is 100% cottons so also biodegradable

👎Maxi-lock is polyester (but I need to use it up before buying a replacement)

Construction

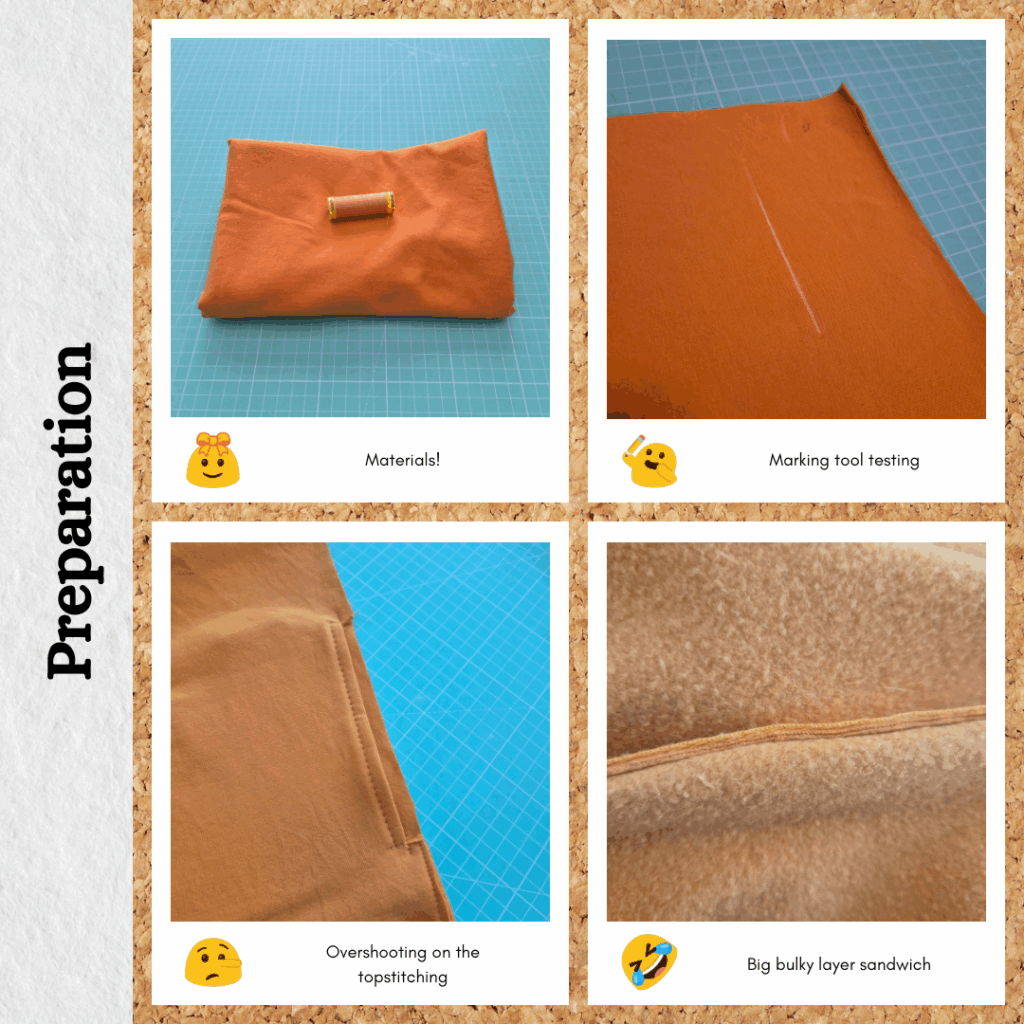

Preparation

Well didn’t get off to a great start lol. I figured out which way the nap was but then proceeded to lay my pattern pieces the opposite way…only realised after cutting out the back and one sleeve. Potential lesson learnt here is don’t cut things when you are shattered from work? But I know I’ll never actually follow that advice so actual lesson learnt here is probably to make sure I orientate the nap with the direction of the pattern pieces so I don’t have to think about flipping things around and can just go on auto-pilot. I managed to make things work by cutting some of the smaller pieces out of the wrong-direction ones.

A random observation – I always find the colour descriptions of fabric interesting. For example, the last two sweaters I made as part of the Yellow Sweater Collection were described as ochre, but my husband called it mustard which is fair,, I can see the similarity and how they could be used interchangeably. But this fabric is called mustard and it’s brighter than what I would have expected. I guess I’m comparing it to the colour of the actual mustard we have in our fridge LOL. But doing a search on the difference, ochre seems to be considered more earthy and mustard more vibrant, so that checks out. But what I found really is interesting is the colour description of the matching thread – Dusky Orange. Colour names are fun haha.

Sewing

I tested out the Frixion and white Clover erasable pens and they didn’t transfer that well. So I also tried the new Prym chalk wheel and it worked better but not the best. I think I need to start using tailors tacks.

I’ve always hated doing inseam pockets, but I think that it’s a bit of a catch-22 where I didn’t have the precision or confidence to do it well so it never turned out well so I hated them. But doing so many welt pockets recently has changed my mentality because inseam pockets are way less fiddly than those haha. So I just made sure to take my time here. One thing I would change next time, is I think I should reduce my stitch length when topstitching the short sides of the pocket opening. Length of 5 is too long to even fit 2 stitches in this area.

When it came to doing the shoulder seams, I remembered that I should stabilise them, so got out the yellow herringbone tape that wasn’t used in the Patchwork Corduroy Bomber Jacket, which was a close enough match. This one had a width of 12mm though, unlike the mustard one I used for the Ochre Simpson Sweat Shirt which was 8mm and could be folded under the seam. So I got a bit confused wondering how this was going to work since 12mm is wider than the seam allowance to 10mm, but then remembered that the tutorial I used was talking about using the clear elastic tape, which is narrow and you also don’t want it showing on the right side. But this is twill tape, so it’s fine to have it showing, so attached it to the front piece so that it would fall on top when the seam was pressed to the back. I did trim the seam ever so slightly so that no fleece would show past the twill tape edge, but the pile is so thick if you look at it from the side it does look like a bit of a sandwich haha. I don’t want to trim it back too much though because of the pile…when it’s uneven I feel you can can feel it a lot.

I forgot that this sweater has side panels, so ended up attaching the side panel to the back first instead of the front. Not a big deal, my tailors ham made it easy to still press the seams prior to topstitching. I decided to also topstitch the sleeve seam to the body down as well.

I thought a bit about if I should try to encase the cuff/hem/neckline seam allowance like I did for the Melange Light Ochre Cleaveland Sweater, but this method does make the seam very bulky. So I’ve made the executive decision that I’ll only use that method if there is gathering involved. I also decided that I should make it habit to secure my overlocked thread ends using my tool all the time. Because I often intend to encase it while topstitching, but then it doesn’t end up happening. Or I trim it when it’s a end that will be secured by another seam, but then it unravels in the meantime a bit making it a bit messy and no longer providing a finish to the seam lol. I also think I have an idea of how to stitch off nicely to make it easier to thread it through the existing loops, especially for when it’s in the round. I’ll try it out for the next sweater 😁

Reflections

So I found this fabric a bit annoying to work with because of the stretch. I think my preference is max 10% stretch for sweaters and hoodies (this one was 20%).

I also think next time I could do a double topstitch. This would secure the seam allowances even more and maybe even hide the layering in places like the shoulder seam. I wonder how well it would work with the edgestitch food though since knits tend to need the walking foot… Or I could try the twin needle? But then I’ll need two spools of thread. Something to think about.

Things I learnt:

- Direct fabric nap with pattern pieces to avoid cutting pieces out the wrong way

- Consider using tailors tacks for fabrics that are hard to mark

- Reduce topstitching stitch length when doing short sections

- Make it a habit to secure overlocker thread tails all the time

Categories: Sewing

Leave a Reply